Cold plasma technology (CPT) is an emerging method for preserving food, increasing its shelf life, and maintaining bioactive compounds. Since CPT doesn’t rely on heat, it’s particularly useful for sterilizing heat-sensitive foods. However, it is still a developing process when it comes to safety assessments. The production of by-products such as ozone, UV rays, and reactive oxygen species during plasma generation can limit its effectiveness and widespread use in the food industry (Ganesan et al., 2020). This web literature looks at how different types of cold plasma are applied to plant and animal products. It also discusses the current state of CPT, its impact on food structures, bioactive compounds, packaging materials, and specific nutrients, as well as the advantages, challenges, and future recommendations for using this technology in the food industry.

Working Principle of cold plasma CPT

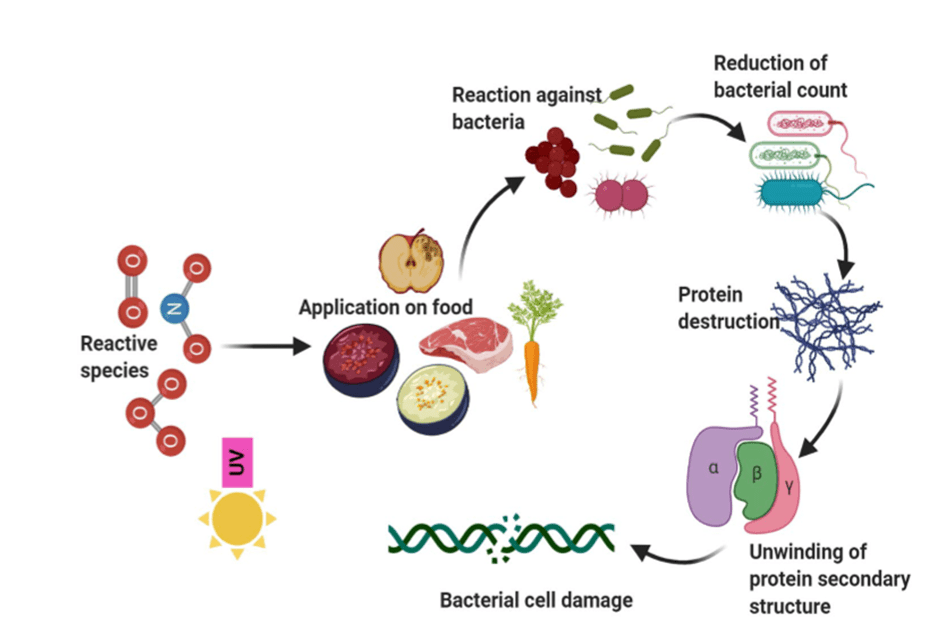

Image 1: A schematic illustration of CPT on different food matrix to inactivate bacteria and viable cells (Ganesan et al., 2020).

Figure 1 illustrates the application of CPT on a food matrix and its mechanism for bacterial inactivation and viable cell damage. When cold plasma (CP) interacts with the food surface, it generates reactive oxygen species (ROS), reactive nitrogen species (RNS), ultraviolet (UV) radiation, charged particles, and electric fields. These components synergistically disrupt bacterial cell membranes, damage DNA, and impair cellular functions, leading to microbial inactivation (Wang et al., 2022). The reactive species penetrate the food matrix, targeting pathogens while preserving the food’s quality. This process highlights CPT potential as a non-thermal, effective technology for enhancing food safety by inactivating bacteria and minimising viable cell counts.

In fact, CP exposure in foods can significantly reduce the total viable count by up to 5 logs, making it an effective non-thermal microbial inactivation method. The mechanism of CPT action differs between Gram-positive and Gram-negative bacteria due to their distinct cell wall structures. In Gram-positive bacteria, CP disrupts cellular integrity by breaking C–O, C–N, and C–C bonds, leading to structural rupture. In contrast, Gram-negative bacteria, which possess an outer membrane rich in lipopolysaccharides, undergo chemical modifications that compromise their viability (Yusupov et al., 2013; Filipić et al., 2020). These differences highlight CP’s targeted antimicrobial effects, making it a promising technology for food safety applications.

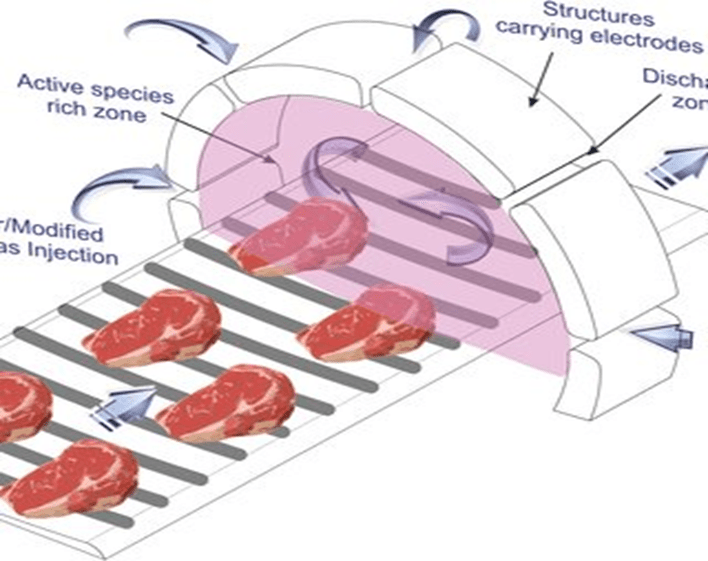

Figure 2: Concept design of cold plasma unit (Misra and Jo, 2017).

Furthermore, CPT operates under a high-voltage electric field (Figure 2), typically ranging from 20 to 60 kV in alternating current. The exposure time varies based on the application, spanning from as short as 5 seconds to a maximum of 60 minutes. Additionally, the frequency used in CP systems generally falls within the range of 50–70 kHz. These parameters influence the effectiveness of plasma treatment in microbial inactivation, food preservation, and quality retention (Misra and Jo, 2017; Ganesan et al., 2020). In CPT, gases such as oxygen, ozone, nitrogen, and helium are used as the primary carrier gases. The velocity of plasma can range from 55 to 95 km/s, depending on the process conditions. The energy sources that drive plasma generation are typically electricity, UV light, and gamma radiation, each contributing to the creation of plasma in different applications (Yusupov et al., 2013; Ganesan et al., 2020).

Cold plasma works to kill microorganisms using three key methods. First, it uses reactive particles, radicals, or charged molecules to damage the cell membranes through chemical reactions. Second, the UV light produced by the plasma harms both the outer membranes and internal parts of the cells. Lastly, when the plasma particles recombine, they generate UV light that can break the DNA inside the microorganisms, preventing them from functioning properly. These processes make cold plasma an effective tool for microbial inactivation (Ansari et al., 2022).

Over the past few decades, foodborne microorganisms pose a significant challenge in the food industry, as they can lead to severe illnesses in humans. Pathogens such as Listeria monocytogenes, Escherichia coli, Salmonella spp., Vibrio spp., Campylobacter jejuni, Staphylococcus aureus, Vibrio parahaemolyticus, etcetera. are commonly found in raw foods and feeds (FSA, 2024), highlighting the need for effective disinfection before packaging (Table 1 & 2). On the other hand, conventional sterilization methods, including chemical, thermal, radiological, and physical treatments, have proven effective but are often complex, time-consuming, and energy-intensive. In contrast, CPT has emerged as an innovative and promising technique in food processing. Unlike conventional methods, CP treatment has minimal impact on the physical, chemical, and nutritional properties of food products, making it a favourable alternative for microbial decontamination (Ansari et al., 2022). It decontaminates food surfaces effectively with minimal impact on nutritional quality, pH, acidity, colour, or texture. For example, some studies have reported minor changes in food properties after CP treatment (Table 1), further research could enhance its application for large-scale commercial use. Cold plasma offers numerous advantages over conventional decontamination methods, including being efficient, safe, cost-effective, environmentally friendly, and capable of preventing secondary contamination during packaging (Ansari et al., 2022).

Table 1. Conditions used for treating vegetables with cold plasma to kill surface microorganisms.

Plasma Type | Treatment Parameters | Microorganisms Killed | Changes in Organoleptic attributes | References | |

| Vegetable | |||||

| Pumpkin | ICDPJ | 17 kV, 20 min | E. coli ATCC 25,922 | Decrease in pH | (Santos et al., 2018) |

| Lettuce | ICDPJ | 2.4 kHz, 34.8kv, 5 min | Aeromonas hydrophila | No Change | (Min et al., 2017) |

| Radish | Microwave- powered plasma | 900 W, 667 Pa, 10 min | S. typhimurium | Decrease in the moisture content | (Oh et al., 2017) |

| Romaine lettuce | DBD | 42.6 kV, 10 min | Escherichia coli O157:H7 | No change | (Min et al., 2017) |

| Cabbage | Microwave-powered cold plasma | 400–900 W, 667 k Pa, 1–10 min | L. monocytogenes | No change | (Lee et al., 2015) |

| Fruits | |||||

| Unpeeled almond | Diffuse coplanar surface barrier discharge | 20 kV, 15 kHz, 15 min | Salmonella | Colour change | (Hertwig et al., 2017) |

| Apple | DBD | 150 W, 12.7 kHz, air, 120 min | E. coli O157:H7 | Reduction of antioxidant | (Ramazzina et al., 2016) |

| Melon | DBD | 12.5 kHz, 15 kV, 30 min | NA | reduction in peroxidase | (Tappi et al., 2016) |

| Strawberries | DBD | 50 Hz, 60 kV, 5 min | Aerobic bacteria and yeasts and moulds | No change | (Misra and Patil, 2014) |

| Cantaloupe | OAUGDP | 9 kV, 6 kHz, 25 °C, 1 min | Salmonella spp. | No change | (Critzer et al., 2007) |

Table 2. Optimal conditions for applying cold plasma treatment to animal-based products for microbial inactivation.

| Product | Voltage | Frequency | Time (min) | Pathogens | References |

| Chicken patties | 70 kV | – | 3 | Listeria innocua, Campylobacter jejuni, Salmonella enterica, and Escherichia coli | (Gao et al., 2021) |

| Fish | 60 kV | 50 Hz | 4 | Mesophile bacteria and Enterobacteriaceae | (Mohamed et al., 2021) |

| Chicken breast | 2 kV | 50 kHz | 2 | L. monocytogenes | (Lee et al., 2016) |

| Pork | 20 kV | 58 kHz | 2 | Listeria monocytogenes, Escherichia coli | (Choi et al., 2015) |

| Pork | 1.2 kV | 20- 100 kHz | 10 | Psychrotrophs, yeast and moulds | (Ulbin-Figlewicz et al., 2015) |

| Chicken muscle | 16 kV | 30 kHz | 8 | L. innocua | (Noriega et al., 2011) |

Key Features of CP Technology:

- Broad-Spectrum Antimicrobial Action: Effectively inactivates a wide range of pathogens, including bacteria, viruses, fungi, and yeasts.

- Eliminates Resistant Microorganisms: Capable of destroying both vegetative cells and spores of pathogens, enhancing food safety.

- Flexible Application: Can be applied to food products with or without packaging, making it a versatile processing technology.

- Limitations in Vacuum Processing: CP is incompatible with vacuum conditions, limiting its use in certain food processing environments.

- Lipid Oxidation Concerns: High-fat foods, such as dairy and meat products, are particularly prone to lipid oxidation due to CP processing, which accelerates oxidative reactions and can negatively impact food quality (Jadhav and Annapure, 2021).

Limitations of cold atmospheric plasma

While CPT has shown promising antimicrobial efficacy, it still has limitations that need to be addressed. Variability in CPT devices, research methodologies, and target microorganisms makes it difficult to standardise results and compare microbial inactivation effectiveness. Additionally, most CP devices are limited to small areas, posing challenges for large-scale applications. The exact mechanism of microbial inactivation by CAP, including its effects on biomolecules like DNA, proteins, and lipids, is still under investigation. Since CP’s reactive species and charged particles depend on factors like the type of gas and atmospheric conditions, further research is needed to fully understand their role. Despite these challenges, ongoing advancements may help overcome these limitations, establishing CAP as a reliable antimicrobial technology (Das et al., 2022).

To summarise, CPT has emerged as a promising antimicrobial solution due to its effectiveness in inactivating resistant microorganisms. However, its efficacy varies depending on factors such as device type, operational gas composition, power settings, and applied voltage. he exact inactivation mechanism remains complex, involving a synergistic effect of reactive species, charged particles, and UV radiation (Das et al., 2022). Therefore, more studies from multiple angles are crucial to better understand the mechanism, optimize the process, and evaluate its effectiveness across different food matrices. Beyond microbial inactivation, CAP serves as a nonthermal food processing technology with minimal impact on food quality. While it holds potential for modifying packaging materials and reducing enzyme activity, challenges remain, including regulatory approval, process optimization, and consumer acceptance. Further research is needed to address safety concerns, enhance its large-scale application, and explore synergies with other treatments.

Empowering sustainable agriculture and food systems through innovation, education, and evidence-based practices

active-packaging Alginate antifungal ATP ATP Bioluminescence bacteria Bioluminescence Blue Mould Chitosan Citrus coatings Cold Plasma Contamination diet Economic Loss Edible Coatings Electrostatic coatings food Food Microbiology Food Packaging Food Safety Food Technology fresh produce gardening Green Mould health Innovation medical Microbial Disinfection Microbiology Natural Preservatives nutrition Penicilium Decay Potassium Alginate Public Health science shelf-life Smart Packaging Sodium Alginate sustainability Sustainable sustainable packaging technology Thyme oil

Leave a comment